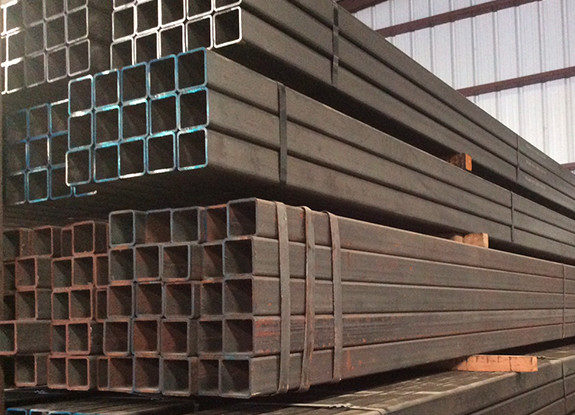

4×4 square steel tubing is a highly versatile material that finds wide application in various industries, including construction, manufacturing, and transportation. This article provides an overview of 4×4 square steel tubing, including its benefits, applications, and manufacturing process. We also discuss the different types of 4×4 square steel tubing available and how they can be used for structural applications.

Introduction:

4×4 square steel tubing is a popular material used in various applications due to its strength, durability, and versatility. It is commonly used in structural applications like building frames, support columns, and trusses. 4×4 square steel tubing is also used in manufacturing heavy machinery and equipment, as well as in the transportation industry. In this article, we will explore the benefits and applications of 4×4 square steel tubing and its manufacturing process.

Benefits of 4×4 square steel tubing:

4×4 square steel tubing offers several benefits over other materials like wood or aluminum. Firstly, it is highly durable and resistant to wear and tear, making it ideal for long-term use in various applications. Secondly, it is highly versatile and can be easily cut, welded, and formed into various shapes and sizes. Thirdly, it is highly cost-effective compared to other materials, making it a preferred choice for many applications. Finally, it is highly sustainable and eco-friendly, as it can be recycled and reused multiple times.

Manufacturing process:

The manufacturing process of 4×4 square steel tubing involves several steps, including raw material preparation, forming, welding, and finishing. The raw materials used for manufacturing 4×4 square steel tubing include hot-rolled steel coils, cold-rolled steel coils, and galvanized steel coils.

These materials are processed and formed into a square shape using advanced equipment like roll forming machines and high-frequency welding machines. The final product is then inspected for quality and finished with surface treatment processes like galvanizing or painting.

Types of 4×4 square steel tubing:

There are several types of 4×4 square steel tubing available, including hot-rolled, cold-rolled, and galvanized steel tubing. Hot-rolled steel tubing is produced at high temperatures and has a rough surface texture, making it ideal for heavy-duty applications. Cold-rolled steel tubing is produced at lower temperatures and has a smooth surface texture, making it ideal for applications that require a high level of precision. Galvanized steel tubing is coated with a layer of zinc, making it highly resistant to corrosion and rust.

Applications:

4×4 square steel tubing finds wide application in various industries, including construction, manufacturing, and transportation. In the construction industry, 4×4 square steel tubing is used for building frameworks, support columns, and trusses. In the manufacturing industry, 4×4 square steel tubing is used for making machinery components and equipment frames. In the transportation industry, 4×4 square steel tubing is used for manufacturing vehicle frames and exhaust systems.

Conclusion:

4×4 square steel tubing is a highly versatile material that finds wide application in various industries, including construction, manufacturing, and transportation. It offers several benefits over other materials like wood or aluminum, including durability, versatility, cost-effectiveness, and sustainability.

The manufacturing process of 4×4 square steel tubing involves advanced technology and modern equipment, ensuring consistent quality and performance. There are several types of 4×4 square steel tubing available, each with its unique properties and applications. 4×4 square steel tubing is an ideal material for structural applications due to its strength, durability, and versatility.