This article provides a comprehensive overview of rolled and welded steel pipe, a versatile and durable solution for various construction and infrastructure projects.

Introduction

Rolled and welded steel pipe is a crucial component in construction and infrastructure projects. This article explores the features, applications, and considerations of using rolled and welded steel pipe, highlighting its importance and versatility in various industries.

Benefits of Rolled and Welded Steel Pipe

Rolled and welded steel pipe offers several advantages in construction and infrastructure applications. It provides high strength, durability, and resistance to various environmental conditions.

The pipe’s seamless design ensures efficient fluid flow and minimizes the risk of leaks, making it a reliable choice for demanding projects.

Applications of Rolled and Welded Steel Pipe

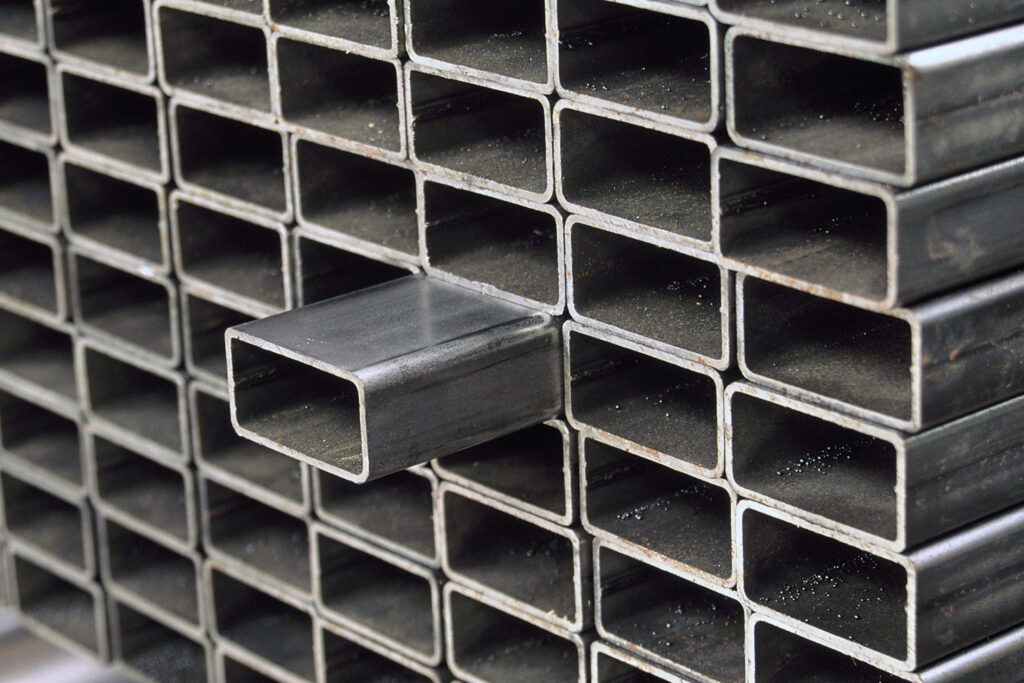

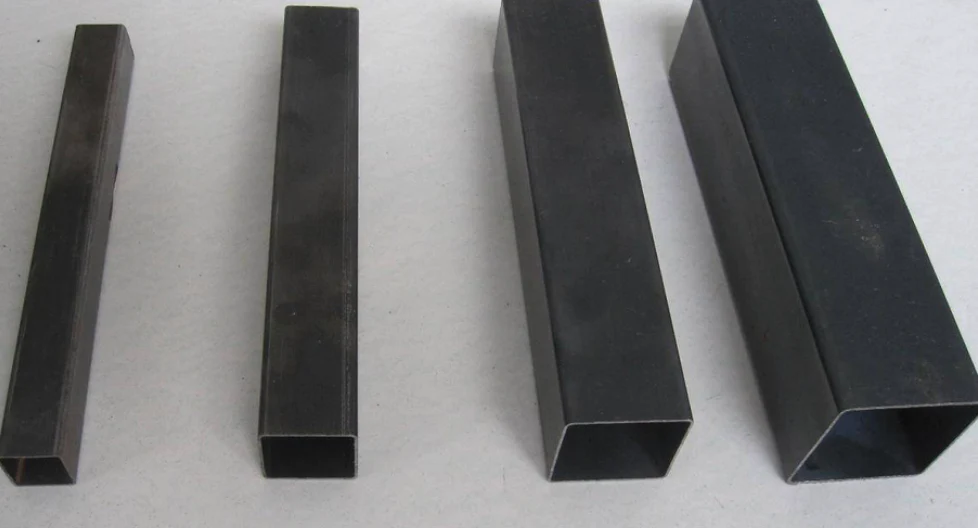

Rolled and welded steel pipe finds applications in diverse sectors, including oil and gas, construction, and infrastructure development.

It is used for oil and gas pipelines, water distribution systems, structural support in buildings, and more. The pipe’s versatility, strength, and corrosion resistance make it suitable for both underground and above-ground installations.

Considerations for Using Rolled and Welded Steel Pipe

Several considerations should be taken into account when using rolled and welded steel pipe. These include selecting the appropriate pipe size, considering the specific project requirements, and ensuring compliance with industry standards and regulations.

Proper installation, regular inspection, and maintenance practices are essential to ensure the pipe’s long-term performance and structural integrity.

Example Scenario

For example, in the oil and gas industry, rolled and welded steel pipe is extensively used for pipeline transportation.

The pipe’s durability and corrosion resistance make it ideal for withstanding the harsh conditions of transporting oil and gas over long distances. Its seamless design ensures efficient flow and minimizes the risk of leaks, ensuring safe and reliable operations.

Conclusion

In conclusion, rolled and welded steel pipe is a reliable and versatile solution for construction and infrastructure projects.

By understanding the benefits, applications, and considerations associated with using rolled and welded steel pipe, businesses can enhance their infrastructure development, ensuring long-lasting performance and structural integrity.

When considering the implementation of rolled and welded steel pipes, it is crucial to work with experienced professionals and adhere to industry standards and regulations.

Regular inspection and maintenance practices will help identify any potential issues and ensure the continued performance of the pipe.