The manufacturing process of spiral welded pipes involves a series of intricate steps that result in durable and high-quality pipes. In this article, we will explore the process of manufacturing spiral welded pipes, from the initial coil preparation to the final inspection. With advanced technology and stringent quality control, this process ensures the production of reliable pipes that meet industry standards. Let’s dive into the world of spiral welded pipe manufacturing and uncover the key aspects of this process.

The Manufacturing Process of Spiral Welded Pipes: A Journey of Strength and Precision

The spiral welded pipes manufacturing process is a complex yet efficient method that combines strength and precision. This process involves various stages, each contributing to the final product’s durability and reliability. From coil preparation to welding and testing, every step is meticulously executed to meet the stringent requirements of the industry.

Coil Preparation and Uncoiling: The Foundation of Quality

The manufacturing process begins with coil preparation, where high-quality steel coils are selected. These coils undergo a thorough inspection to ensure they meet the required standards. Subsequently, the coils are uncoiled and leveled to prepare them for the next stage.

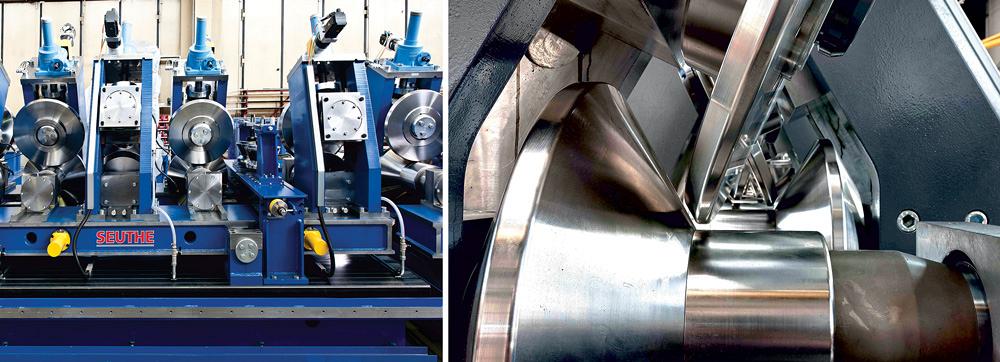

Forming and Welding: Crafting a Seamless Connection

The forming and welding stage is crucial in creating a seamless connection in spiral welded pipes. The uncoiled steel strip is shaped into a spiral form using specialized machines. The edges of the strip are then welded together continuously, ensuring a strong and consistent bond. This spiral welding technique enhances the pipe’s structural integrity and enables it to withstand high-pressure applications.

Finishing and Inspection: Ensuring Quality and Compliance

After the welding process, the spiral welded pipes undergo a series of finishing treatments. These treatments include trimming excess weld material, smoothing the weld surface, and removing any imperfections. This ensures a smooth and uniform appearance while maintaining the pipe’s strength.

Following the finishing stage, the pipes undergo a rigorous inspection to ensure compliance with industry standards. Non-destructive testing techniques, such as ultrasonic testing and X-ray inspection, are employed to detect any defects or discontinuities. This thorough inspection guarantees the quality and reliability of the spiral welded pipes.

Advantages of Spiral Welded Pipes

- High Strength: Spiral welded pipes exhibit excellent strength due to their continuous weld seam. This strength makes them suitable for applications that require resistance to high-pressure environments.

- Versatility: Spiral welded pipes can be manufactured in various sizes and diameters to meet specific project requirements. This versatility allows for a wide range of applications across different industries, including oil and gas, construction, and water transportation.

- Cost-Effectiveness: The manufacturing process of spiral welded pipes offers cost advantages compared to other pipe manufacturing methods. The continuous production process, combined with efficient material utilization, contributes to lower production costs.

Conclusion:

The manufacturing process of spiral welded pipes exemplifies precision, strength, and efficiency. From coil preparation to final inspection, each stage plays a vital role in ensuring the production of durable and high-quality pipes. The seamless connection achieved through spiral welding, along with the strict quality control measures, results in pipes that meet industry standards. With their exceptional strength, versatility, and cost-effectiveness, spiral welded pipes continue to be a preferred choice for a wide range of applications across various industries.

-1024x783.jpg)

-e1690271129712.jpg)

-e1690271189252.jpg)