From structural support in buildings to creating frameworks for machinery and equipment, this tubing offers strength, stability, and design flexibility. Understanding the capabilities of 4×4 square steel tubing enables industries to make informed decisions and achieve optimal results in their projects.

Exploring the Characteristics of 4×4 Square Steel Tubing:

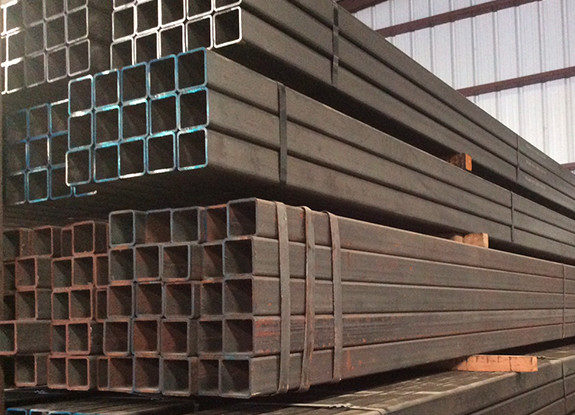

4×4 square steel tubing is known for its sturdiness and precision dimensions. It is made from high-quality steel, providing excellent strength and durability. The square shape of the tubing offers inherent stability and resistance to bending.

Making it ideal for structural applications. Additionally, the precise dimensions of 4×4 square steel tubing allow for easy fabrication and compatibility with various connectors and fasteners.

Advantages and Benefits:

The use of 4×4 square steel tubing offers several advantages. Firstly, its robust construction provides superior strength, making it suitable for heavy-duty applications. Secondly, the square shape allows for efficient load transfer, ensuring structural stability and integrity. Moreover, the design flexibility of 4×4 square steel tubing enables customization and adaptability to specific project requirements.

Applications of 4×4 Square Steel Tubing:

4×4 square steel tubing finds applications across various industries. In construction, it is commonly used for structural support in buildings, such as columns, beams, and trusses. In the manufacturing sector, this tubing is utilized for creating frameworks and supports for machinery and equipment. Additionally, 4×4 square steel tubing is employed in fabrication processes to construct frames, racks, and workbenches.

Example scenario:

For example, in the construction of a commercial building, 4×4 square steel tubing is used for the framework of the structural columns. The tubing’s strength and stability ensure the structural integrity of the building, supporting the weight of multiple floors and providing resistance against external forces.

In conclusion:

4×4 square steel tubing is a versatile and reliable material widely used in various industries. Its characteristics, including strength, stability, and design flexibility, make it suitable for a wide range of applications. By understanding the advantages and applications of 4×4 square steel tubing, industries can optimize their projects, enhance structural integrity, and achieve superior results.