Straight seamless steel pipes come in different specifications that vary in size, shape, and material composition. These differences affect the pipes’ performance and suitability for different applications. This article examines the differences in specifications of straight seamless steel pipes, including their sizes, wall thickness, materials, and manufacturing processes.

Introduction to Straight Seamless Steel Pipes

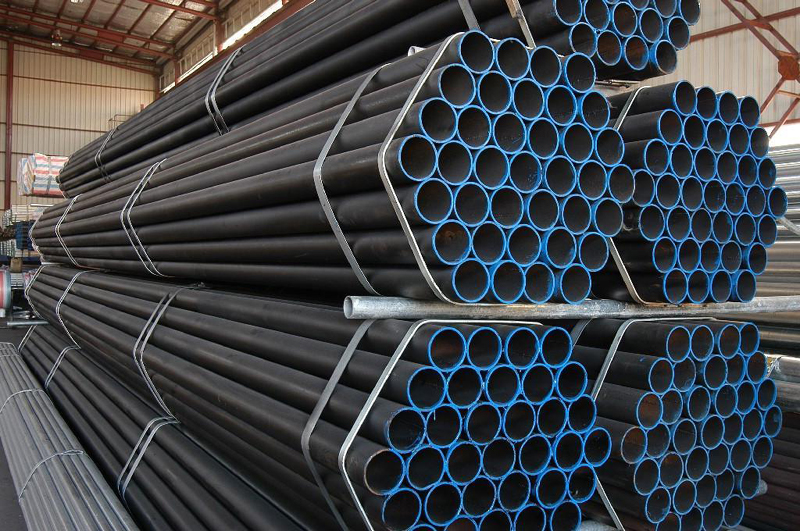

Straight seamless steel pipes are widely used in various industries, including oil and gas, construction, automotive, and manufacturing. These pipes are prized for their durability, high strength, and resistance to corrosion and high temperatures. However, not all straight seamless steel pipes are created equal. They come in different specifications that affect their properties and performance.

Specifications of Straight Seamless Steel Pipes

The specifications of straight seamless steel pipes include their sizes, wall thickness, materials, and manufacturing processes. The most common sizes range from 1/8 inch to 24 inches in diameter, with varying wall thicknesses. The materials used to make these pipes include carbon steel, stainless steel, and alloy steel, each with unique properties and characteristics.

Differences in Material Composition

Carbon steel pipes are the most widely used and affordable option, suitable for most applications that do not require high corrosion resistance or extreme temperatures. Stainless steel pipes are more expensive but offer superior corrosion resistance and durability, making them ideal for harsh environments and specialized applications. Alloy steel pipes combine different metals to enhance their properties, such as strength, corrosion resistance, or heat resistance.

Manufacturing Processes

Straight seamless steel pipes are made through two main processes: hot rolling and cold drawing. Hot rolling involves heating a metal billet and rolling it into a seamless pipe shape. This process is suitable for large-diameter pipes and high-temperature applications. Cold drawing involves pulling a metal rod through a die to create a seamless pipe with a smaller diameter and smoother surface. This process is ideal for precision applications that require tight tolerances and a polished finish.

Wall Thickness and Pressure Ratings

The wall thickness of straight seamless steel pipes varies depending on the pipe’s diameter and material. Thicker walls can withstand higher pressure and stress, making them suitable for heavy-duty applications. Pressure ratings indicate the maximum pressure that a pipe can handle before failure. Different specifications of straight seamless steel pipes have different pressure ratings, which must be carefully considered when selecting the right pipe for a given application.

Conclusion

In conclusion, straight seamless steel pipes come in different specifications that affect their size, shape, material composition, and manufacturing process. These differences must be carefully considered when selecting the right pipe for a given application. By understanding the differences in specifications, one can choose the most suitable straight seamless steel pipe for their needs and ensure optimal performance and durability.

.jpg)

.jpg)

.png)