Discover the intricate process of manufacturing 2×2 square tubing, a versatile and widely-used structural component in various industries. This article provides a detailed insight into the production of 2×2 square tubes, from material selection and forming to finishing and quality control.

Understanding the manufacturing process empowers engineers, architects, and construction professionals to make informed decisions, ensuring the highest quality and performance of 2×2 square tubing for their projects. Join us as we explore the journey of 2×2 square tube production, ensuring reliability and efficiency in industrial applications.

An Overview of 2×2 Square Tubing

2×2 square tubing is a widely used structural element, favored for its strength and versatility in construction and industrial applications. Understanding its production process is vital for ensuring high-quality and reliable tubing for diverse projects.

Material Selection for 2×2 Square Tube Production

- Steel Choice: Selecting the appropriate type and grade of steel to meet the desired mechanical properties and structural requirements.

- Coil Forming: Starting with steel coils, which are precision-formed into flat strips for further processing.

Forming Process: Transforming Flat Strips into 2×2 Square Tubes

- Slitting: Cutting the flat strips to the desired width for the square tube.

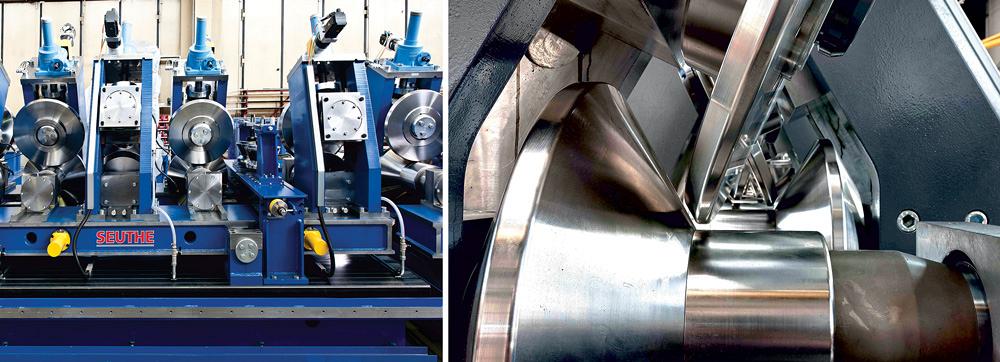

- Roll Forming: Passing the strips through specialized rollers to gradually shape them into square tubes.

- Welding: Seam welding the edges of the tube to create a continuous and seamless structure.

Finishing and Surface Treatment

- Cutting to Length: Precisely cutting the square tubes to the required length for specific applications.

- Deburring: Removing any rough edges or burrs from the tube to ensure smooth and safe handling.

- Surface Coating: Applying coatings, such as galvanization or powder coating, to enhance the tube’s corrosion resistance and appearance.

Quality Control Measures

- Dimensional Inspection: Ensuring the square tubes meet the specified size and tolerances.

- Visual Inspection: Identifying any surface defects or imperfections that may affect the tube’s integrity.

- Mechanical Testing: Conduct various tests, such as tensile and compression tests, to assess the tube’s mechanical properties.

Examples of 2×2 Square Tube Applications

Examples of 2×2 square tubing applications in construction, manufacturing, and engineering projects demonstrate its versatility and significance in various industries.

Conclusion

Understanding the intricacies of 2×2 square tube production is vital for ensuring high-quality and reliable structural components. From material selection and forming to finishing and quality control, each step contributes to the tube’s performance and durability. By mastering the manufacturing process, engineers and construction professionals can confidently incorporate 2×2 square tubing in their projects, ensuring optimal results and long-lasting performance.