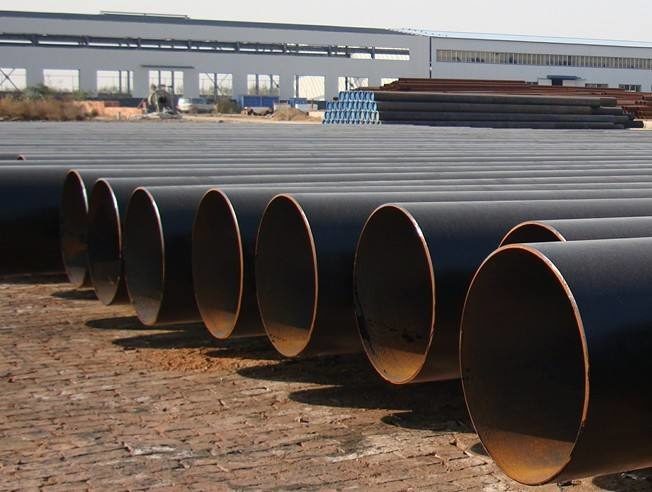

Spiral welded pipes are a popular choice in many industries due to their numerous advantages over other types of pipes. This article will discuss the various advantages of spiral welded pipes, including their strength, durability, and suitability for a range of applications.

Introduction to Spiral Welded Pipe Advantages

Spiral welded pipe advantages are numerous and make this type of pipe a popular choice in various industries. The spiral welding process used to manufacture these pipes results in several benefits over other types of pipes.

Strength and Durability of Spiral Welded Pipe

Spiral welded pipes are known for their strength and durability, making them suitable for use in high-pressure and high-temperature applications. The spiral welding process creates a continuous and uniform weld that improves the pipe’s strength and resistance to deformation.

The flexibility of Spiral Welded Pipe

Spiral welded pipes are highly flexible, making them easy to install and transport. They can be bent and curved to fit the required shape and size, making them ideal for use in applications where conventional straight pipes are not suitable.

Corrosion Resistance of Spiral Welded Pipe

Spiral welded pipes are highly resistant to corrosion, making them suitable for use in harsh and corrosive environments. The welding process creates a uniform and continuous seam that prevents water and other corrosive substances from penetrating the pipe.

Cost-Effectiveness of Spiral Welded Pipe

Spiral welded pipes are a cost-effective choice for many applications. They require less material than other types of pipes, resulting in lower material and transportation costs. In addition, the spiral welding process is highly efficient, resulting in lower labor and production costs.

Availability of Spiral Welded Pipe

Spiral welded pipes are widely available from manufacturers and suppliers worldwide. They are available in different sizes, grades, and specifications to meet specific requirements.

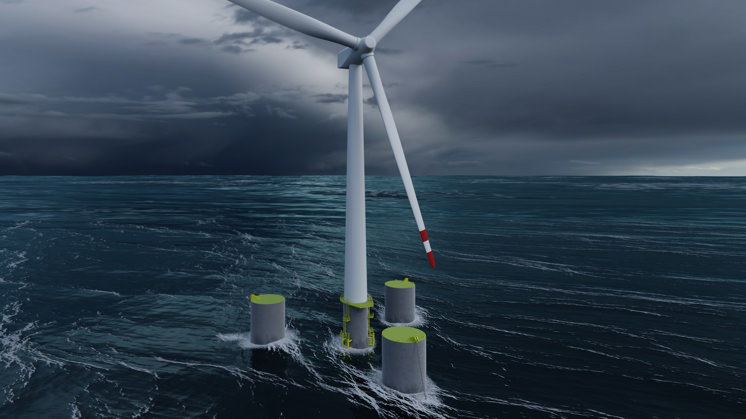

Applications of Spiral Welded Pipe

Spiral welded pipes are used in a wide range of applications, including oil and gas pipelines, water pipelines, structural supports, and piling. They are also used in the construction of bridges, tunnels, and other infrastructure projects.

Conclusion

Spiral welded pipes offer numerous advantages over other types of pipes. They are strong, durable, flexible, and highly resistant to corrosion. They are also cost-effective and widely available, making them a popular choice in many industries. With their numerous benefits, spiral welded pipes are an excellent choice for a range of applications.

In summary, the advantages of spiral welded pipes include their strength, durability, flexibility, corrosion resistance, cost-effectiveness, availability, and suitability for a range of applications. By considering these advantages, industries can make an informed decision when selecting pipes for their projects.

-1024x683.jpg)

.jpg)

-1-1024x768.jpg)

-1024x576.jpg)

.jpg)

.png)

.jpg)

.png)