Steel fiber i95 is a high-performance reinforcement material that can significantly enhance the durability and toughness of concrete structures. This article explores the benefits of using steel fiber i95 in concrete, its properties, and its applications. We will also discuss the advantages of steel fiber i95 over traditional reinforcement materials and provide examples of successful projects where it has been utilized.

What is Steel Fiber i95?

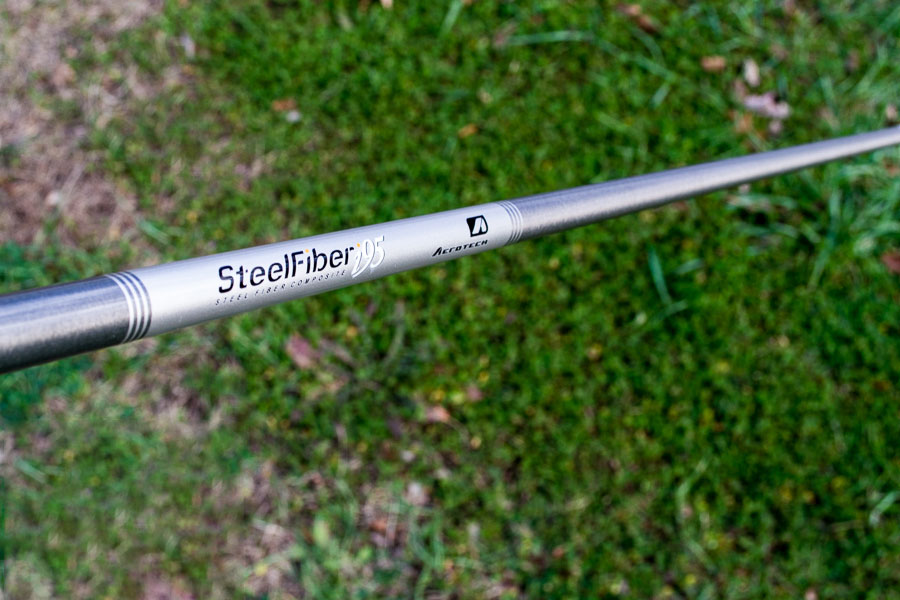

Steel fiber i95 is a type of Aerotech steel fiber that is commonly used to reinforce concrete. It is a high-tensile strength material with excellent ductility and durability. It is typically made from low-carbon steel wires that are cut and cold-drawn into fibers of various lengths and diameters. These fibers are then mixed into the concrete during the batching process to form a composite material with superior mechanical properties.

Properties of Steel Fiber i95

Steel fiber i95 has several unique properties that make it an excellent reinforcement material for concrete. It has a high tensile strength, which allows it to resist tensile stresses and prevent cracking. It also has good ductility, which means that it can deform without breaking, absorbing energy, and preventing sudden failure. Additionally, steel fiber i95 has good corrosion resistance, which makes it suitable for use in harsh environments.

Applications of Steel Fiber i95

The material is commonly used in a variety of concrete applications, including industrial flooring, precast concrete elements, and shotcrete. It is also used in tunnel linings, bridge decks, and airport runways. Its high tensile strength and ductility make it ideal for applications where heavy loads, vibrations, and impact are expected. Steel fiber i95 can also enhance the durability and resistance of concrete structures to fire, freeze-thaw cycles, and abrasion.

Advantages of Steel Fiber i95

Steel fiber i95 offers several advantages over traditional reinforcement materials, such as rebar and welded wire mesh. It provides higher crack resistance, improved flexural strength, and better fatigue resistance. It also allows for faster construction, as it eliminates the need for manual placement and tying of rebar. Furthermore, steel fiber i95 can reduce the amount of concrete required for a project, resulting in cost savings and environmental benefits.

Successful Projects with Steel Fiber i95

There have been many successful projects where steel fiber i95 has been utilized to enhance the durability and toughness of concrete structures. For example, in the construction of the Dubai Mall, steel fiber i95 was used to reinforce the concrete slabs in the parking garage, providing enhanced crack resistance and durability. In the construction of the new Istanbul Airport, steel fiber i95 was used in the concrete pavements and taxiways, improving their resistance to heavy aircraft traffic and freeze-thaw cycles.

Conclusion:

In summary, steel fiber i95 is a high-performance reinforcement material that can significantly enhance the durability and toughness of concrete structures. Its unique properties make it an ideal choice for a variety of applications, and its advantages over traditional reinforcement materials provide cost savings, faster construction, and environmental benefits. With successful projects around the world, steel fiber i95 continues to be a popular choice among engineers and contractors for strengthening and improving the performance of concrete structures.